product description

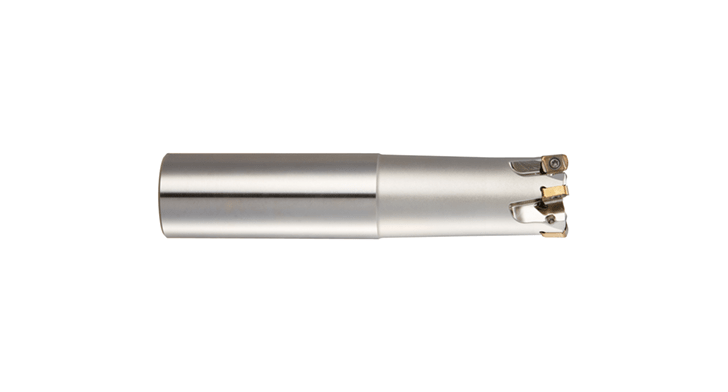

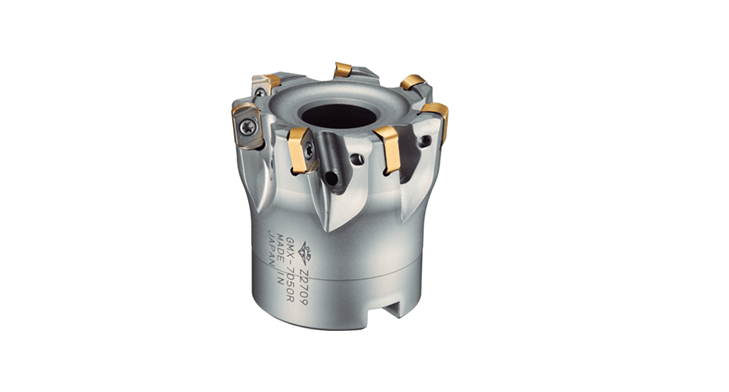

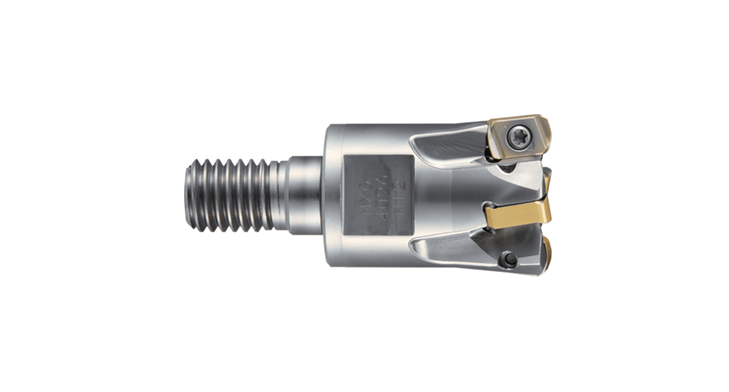

The QM Max G2 is a double-sided insert with 4 cutting edges. This geometry is designed for roughing and achieving high metal removal rates. The one size insert covers a range of diameters from 5/8” to 2” bodies. Max depth of cut on this high feed is .040” and can handle a heavy chip load. There are two styles of inserts for hard milling, one being a chip breaker and the other a flat top. The flat top “ENMQ” insert is the best for 60 HRC material and interrupted cut. This cutter also has an insert that is excellent for machining high nickel alloys.

Inserts

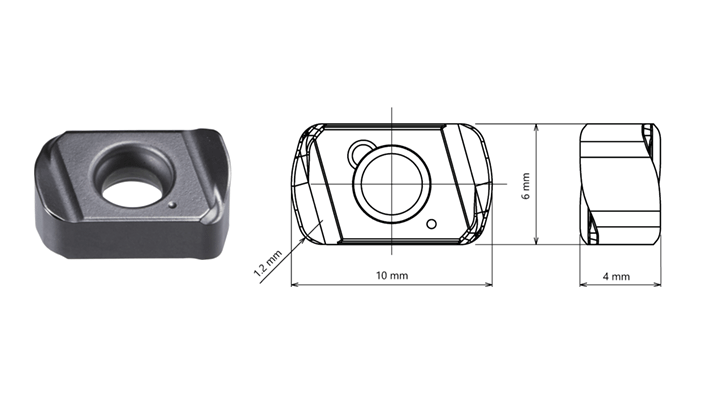

ENMU100412ZER-PH

Double sided High Feed insert with 4 cutting edges.

Available grades: JC8118 JC7560 Programmable Corner Radius: : 1.5MM

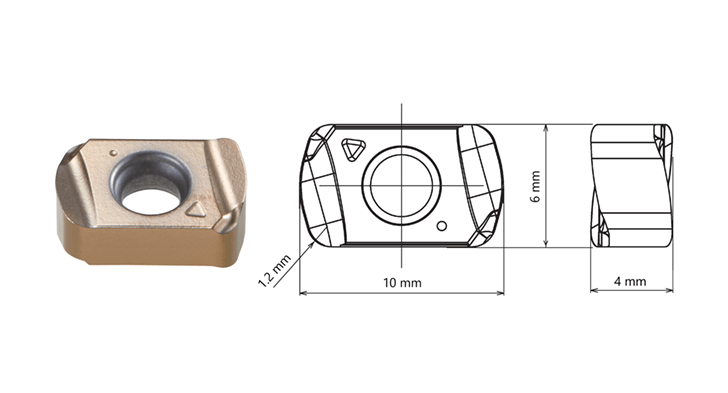

ENMU100412ZER-SL

Double sided high feed insert with 4 cutting edges. Made for high-temp alloys.

Available grades: JC7550 Programmable Corner Radius: : 1.5MM

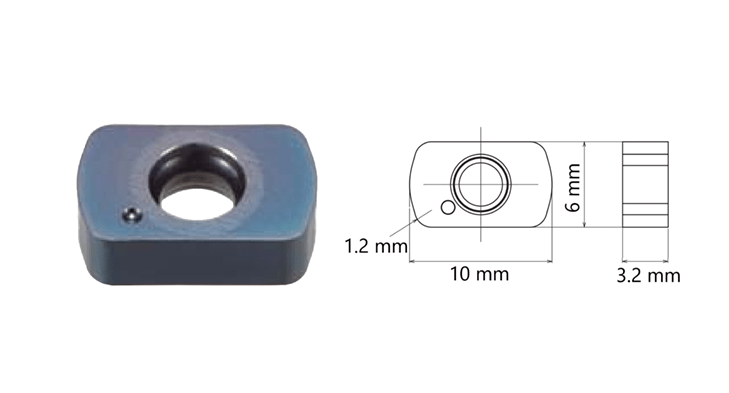

ENMQ100312ZER

Double sided High Feed insert for hardened materials up to 60 HRC.

Available grades: DH102 Programmable Corner Radius: : 1.5MM

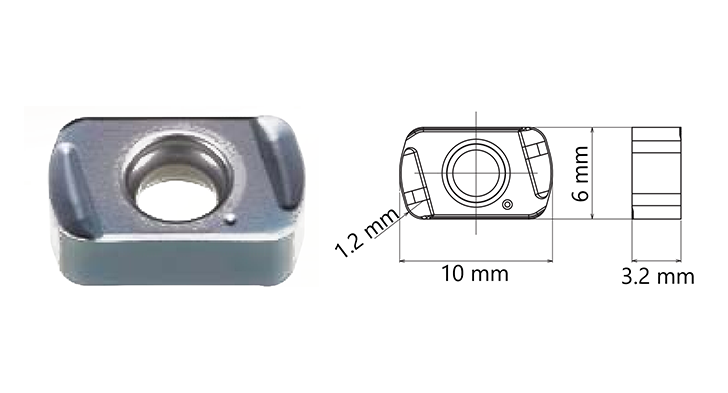

ENMU100312ZER-HL

4 cornered insert with chip breaker for hardened materials up to 60 HRC.

Available grades: DH102 Programmable Corner Radius: : 1.5MM