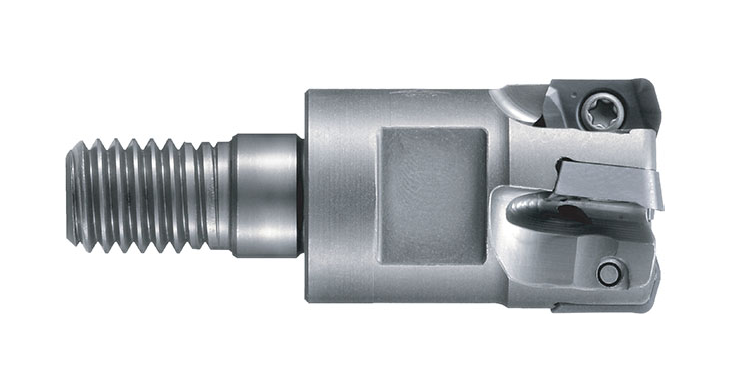

product description

The QM Max has a variety of inserts that can cut a wide range of material all while using the same body. High feed inserts have grades that can machine materials anywhere from Inconel to 60 HRC weld, while the square shoulder inserts can mill anything from aluminum to super duplex stainless. The ground finish inserts include grades for high-hardened steels and a CBN tipped insert for cast iron. This positive insert geometry is very free machining and perfect for 5-axis spindles.

Inserts

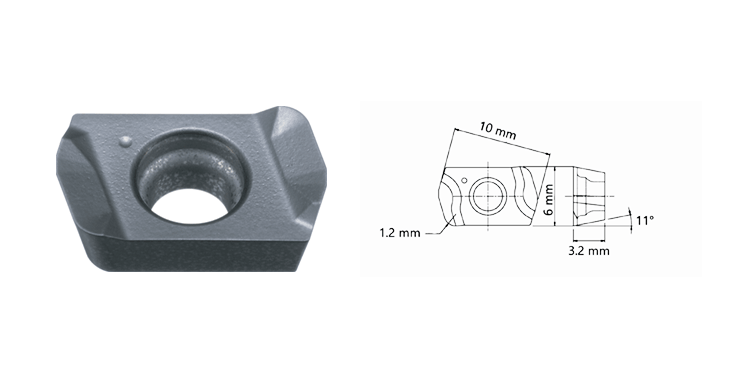

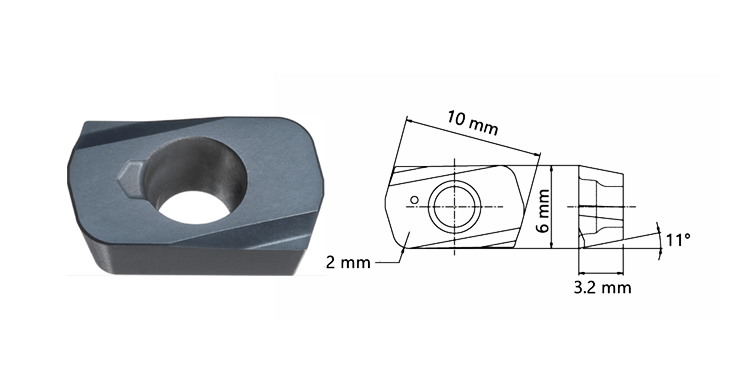

EPMT100312ZER

High Feed insert with Chip Breaker for long reach and high temp alloys.

Available grades: JC8118 JC8050 JC7560 DS118 DS150

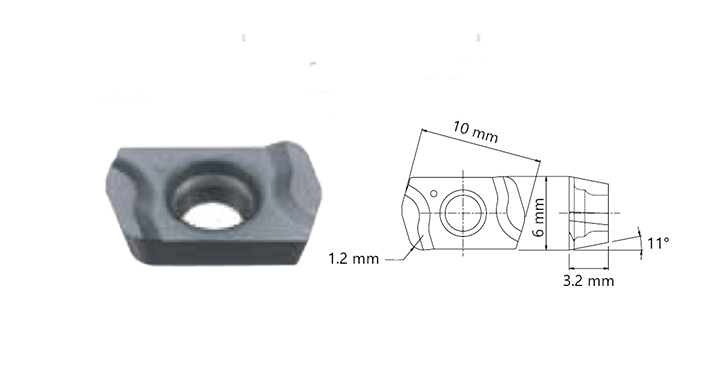

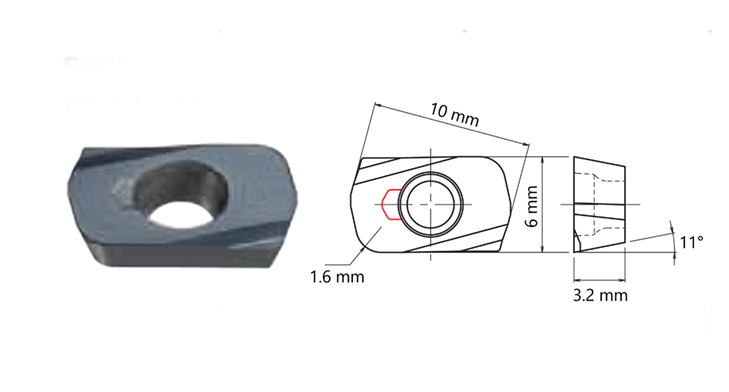

EPMW100312ZER

Chip breaker insert recommended for interupted cut.

Available grades: JC8118, JC8050

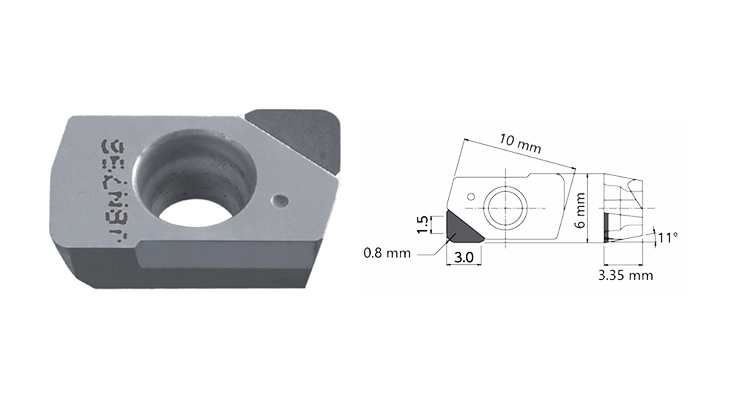

EPMW100312ZTR

High Feed insert for machining high hard materials.

Corner Radius: 1.5MM Available grades: JC8118 DH102

EPHW100316ZER

Flat top insert for milling hard materials up to 60 HRC.

Available grades: : JC8118, DH102

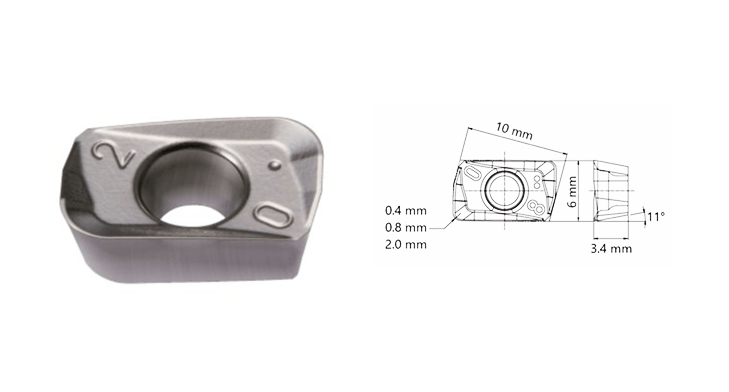

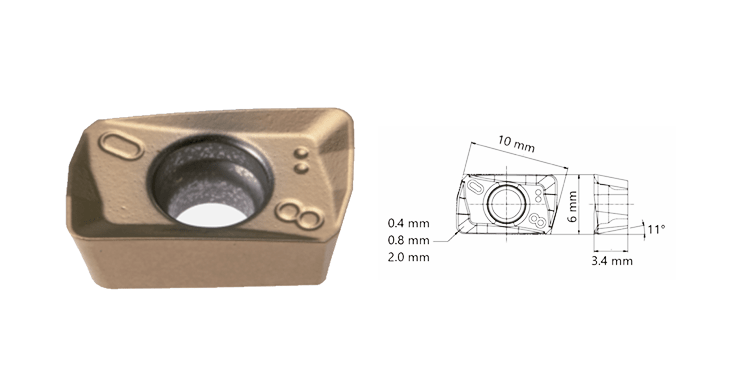

ZPMT1003**ZER-NL

90° Square shoulder for Aluminum.

Corner Radius: 0.4MM 0.8MM 2.0MM Available grades: FC18

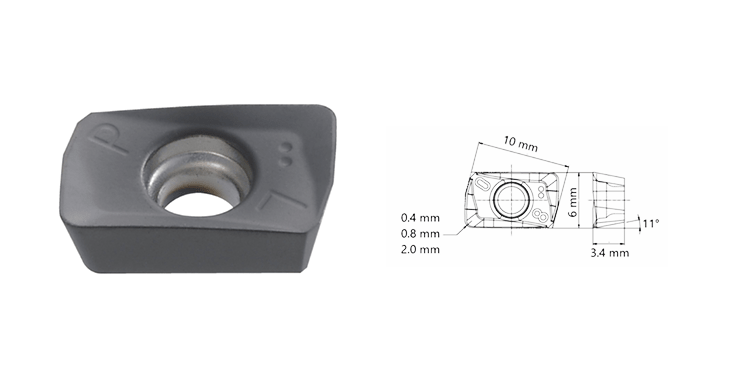

ZPMT1003**ZER-PL

90° Square Shoulder for semi finish & finish.

Corner Radius: 0.4MM 0.8MM 2.0MM Available grades: JC8118 JC8050 DH102 CX75

ZPMT1003**ZER-SL

90° Square Shoulder for high-temp alloys.

Corner Radius: 0.4MM 0.8MM 2.0MM Available grades: JC7518 DS118

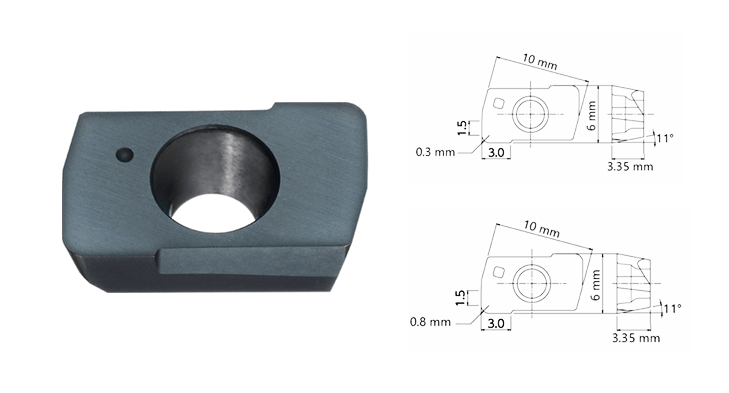

YPHW1003**ZER-**

"Mirror Insert" for finishing sidewall and flat surfaces.

Corner Radius: 0.3MM 0.8MM Available grades: JC8015 DH102 CX75

YPHW100308ZTR-F1

CBN insert for finishing flat surfaces and vertical walls.

Corner Radius: 0.8MM Available grades: JBN795

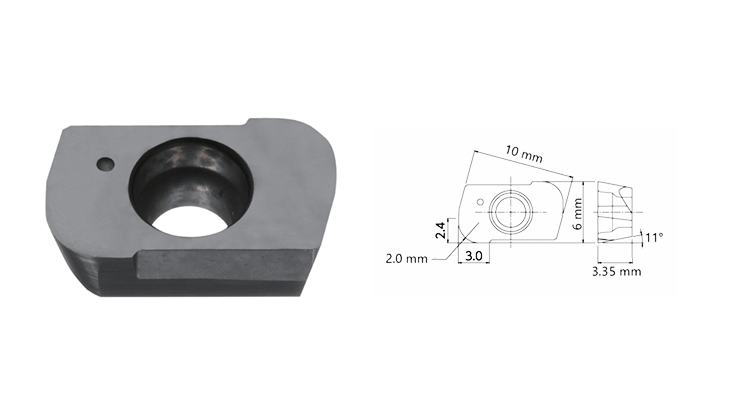

YPHW100320ZER-24

"Mirror Insert" for finishing sidewall and flat surfaces.

Corner Radius: 2.0MM Available grades: JC8015 DH102