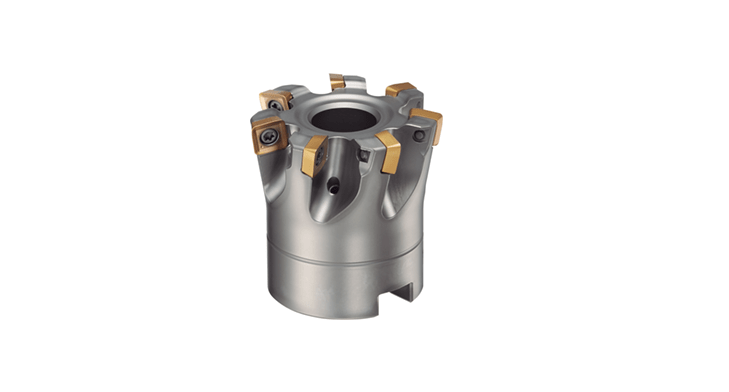

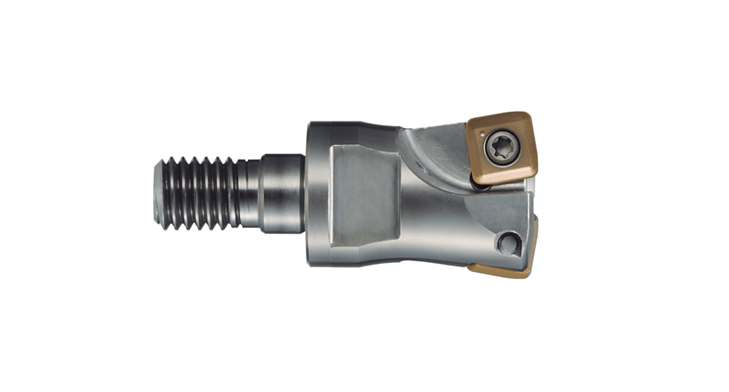

product description

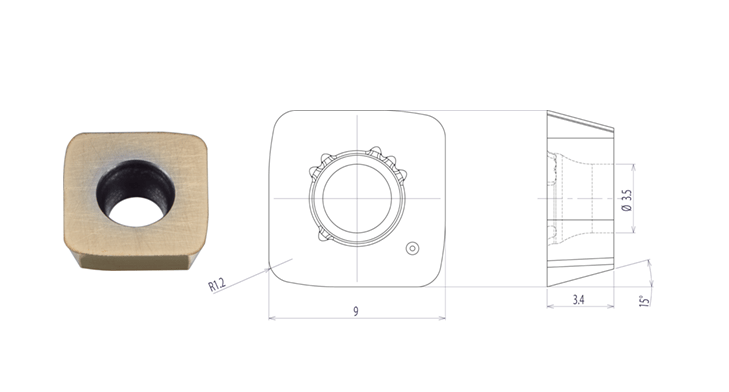

This 9mm square insert was specifically designed for machining aerospace components. The 4 cornered inserts are made for cutting Ni-base heat resistant alloys, titanium alloys, and hardened stainless steels. These fine pitched pockets allow a high number of teeth for faster feed rates. Also, the inserts are ground in order to achieve excellent tool life and the best surface finish. The maximum depth of cut for this insert 0.9 mm. The flat top insert is ideal for face milling, while the chip breaker is good for pocketing and long reach applications.

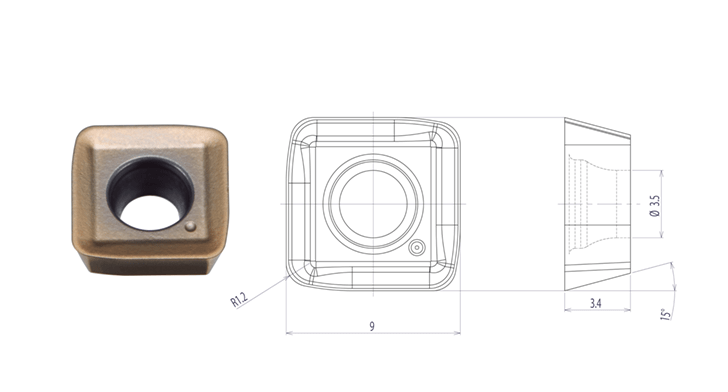

Inserts

SDET090312ZDER-SM

High feed insert designed for high-temp alloys. "chip-breaker" geometry for pocketing and long reaches.

Available grades: JC7550 DS150 DS118 Programmable Corner Radius: : 2MM

SDEW090312ZER

High feed insert designed for high-temp alloys. "Flat-top" geometry for face milling and stable machining.

Available grades: JC7550 DS118 DS150 Programmable Corner Radius: : 2MM